Description

TPR anti-impact and cut-resistant Mechanic Gloves (TPR-701)

These TPR anti-impact and cut-resistant Mechanic Gloves (TPR-701) have been widely praised in many industries for their excellent protection performance and comfortable wearing experience. Its anti-collision design effectively reduces the risk of hand injury from accidental impact. At the same time, anti-cutting materials provide strong protection, giving staff more peace of mind when handling sharp objects.

Product Specification:

| Material | Liner-13 gauge nylon and HPPE and steel fibre, Coating-sandy nitrile, and TPR palm-coated |

| Performance Level | EN388 (cut level: A3/A4/A5/A6) |

| Size | 7(S)-11(XXL) |

| Normal Package | 12 pairs /polybag, 120pairs/carton |

| Application | Automotive assembly, Glass Industry, Sports, Oil & Gas & Mining, Steel & Metal, etc. |

| MOQ | 500 dozens (1dozen=12pairs) |

| Logo | The LOGO can be customized. |

| Characteristics | Dexterity, Sensitivity, Anti-Impact, Anti-slip, Anti-cut, Oil Proof |

| Remarks | OEM is accepted, Design and color can be customized. |

Product Details:

1. Multi-material fusion and composite structure design:

- High-strength 13 gauge nylon HPPE and steel fibre are used in the lining of mechanic gloves, which greatly improves the wear resistance, tear resistance, and anti-cutting performance, forming an impenetrable anti-cutting barrier and effectively resisting the threat of sharp objects.

- Nitrile matte coating is specially treated to create a microscopic texture, increase the surface friction coefficient, provide excellent slip resistance and grip stability, and maintain excellent handling performance in wet or greasy environments.

2. Thermoplastic rubber (TPR) enhanced protection system:

- Innovative introduction of TPR material on the back of mechanic gloves, using polymer thermoplastic rubber injection moulding process, seamlessly integrated into the glove body to form a strong protective shell.

- TPR materials have excellent impact resistance and elastic recovery ability, effectively absorbing and dispersing external impact forces, and reducing the risk of hand injury.

- TPR’s molecular chain structure gives it good weather resistance and chemical stability, maintaining the protective performance and service life of gloves even in extreme environments.

3. High cutting grade and standard compliance:

- The mechanic gloves have been cut to international standards and can reach various cutting grades from A3 to A7, meeting the stringent requirements of cut-resistant gloves in the industrial sector.

- The design and manufacturing process of gloves strictly follows international standards such as ANSI/ISEA 105-2016 to ensure that their collision resistance can meet ANSI-level certification standards, providing users with reliable safety.

4. Personalized customization service:

- We offer a comprehensive TPR custom design service, using advanced CAD modelling and simulation analysis technology to tailor the TPR protection part of the glove to the specific needs of the customer and the size of the hand.

- Personalized protection is achieved by adjusting parameters such as thickness, hardness, and shape of the TPR material to ensure that the gloves achieve the required level of protection while providing the best comfort.

- Customization services also include the customization of details such as glove colour, size, palm coating type, and thickness to meet the individual needs of different industries, jobs, and specific application scenarios.

With its advanced multi-material fusion technology, innovative thermoplastic rubber reinforced protection system, high cutting grade and standard compliance, and personalized customized service, the TPR anti-impact and cut-resistant Mechanic Gloves provide users in the industrial sector with an excellent hand protection experience, helping to improve work efficiency and safety.

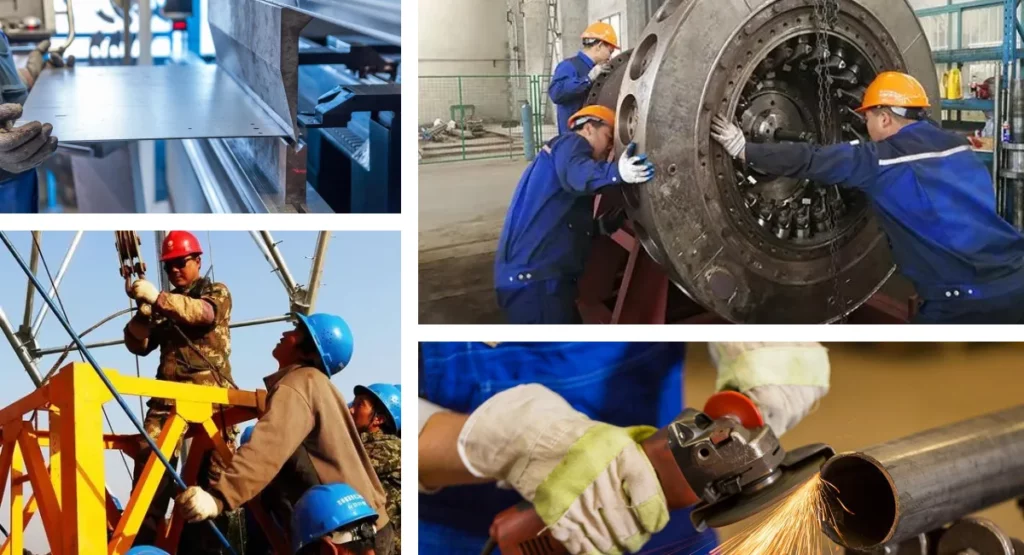

Application:

When you work in industries such as mechanical maintenance, construction, automotive, glass, steel, and metal, your work environment and the nature of your work dictate that there is a higher risk for hand safety. These risks can come from sharp tools, heavy impacts, sliding objects, or exposure to hazardous substances.

As a result, they need a glove that offers comprehensive protection, and the TPR anti-impact and cut-resistant Mechanic Gloves are ideal for meeting this need.

1. Mechanical Maintenance & Automotive: When performing large equipment repairs, handling mechanical components, and automotive parts, or performing maintenance operations, workers are often exposed to sharp metal edges, hot surfaces, hazardous chemicals, and oily surfaces.

These Mechanic Gloves protect against cuts, collisions, and oil resistance, ensuring hand stability and dexterity when gripping and operating tools.

2. Construction industry: Construction sites are filled with a variety of construction materials, tools, and mechanical equipment, such as steel, stone, metal, cutting machinery, tower crane maintenance, crane maintenance, etc.

These materials and types of equipment come with sharp edges, which can easily cause hand cuts. Equipment maintenance and material handling can easily cause hand collisions. The TPR material of these mechanical gloves can provide extra impact protection and reduce the risk of hand injuries due to accidental collisions.

3. Glass industry: When handling glass materials, workers face the risk of cuts and puncture wounds. Glass shards and sharp edges can easily cut the skin. The cut-resistant design of these gloves effectively protects against these hazards, and the TPR impact-resistant material avoids crushing the hand when handling glass, thus ensuring that the hand is protected from injury.

4. Steel and metal industry: In the steel and metal processing process, staff need to handle a variety of metal materials and parts. For example, cutting, handling, secondary processing, etc., these metal materials are with sharp or burr edges and, some of the material is heavy, easy to cause hand cuts and back of-hand bruises. In addition, prolonged contact with metal materials can also lead to hand fatigue and joint damage.

These Mechanic Gloves can provide comprehensive protection, reduce hand fatigue, and provide protection for the operator’s hand health.

To summarize, by providing multiple protections such as anti-cut, anti-slip, and anti-collision, as well as through the comfort and dexterity of its material, these TPR anti-impact and cut-resistant Mechanic Gloves meet the hand safety needs of operators in the mechanical maintenance, construction, automotive, glass, steel, and metal industries.

Another mechanical glove recommendation you might like: Anti-Impact And Cut-Resistant Mechanical Work Glove(TPR-1101)