How do anti-static gloves work?

The anti-static principle of anti-static gloves is based on the anti-static mechanism of conductive fibres. The anti-static mechanism of the conductive fibres is to create a corona discharge between the conductive fibres. Corona discharge is a very gentle form of discharge. When the static voltage reaches a certain value, a non-sparking corona discharge is generated to eliminate static electricity. Conductive fibres have good electrical conductivity and durability and maintain good durability and anti-static properties, especially in low-humidity environments, so they are widely used in anti-static gloves.

What are the anti-static gloves test standards and procedures?

It is important to understand the test methods and test standards for anti-static gloves. There are two categories of megohmmeters for testing, 100V and 10V (±5%), of which 100V is used to test ≧1X106 ohms and 10V is used to test <1X106 ohms. At the same time, you need an anti-static wrist strap, a metal plate, and a static voltmeter.

The test must be carried out according to certain procedures. The specific procedures are as follows:

- The temperature and humidity conditions at the time of inspection are temperature: 23±3oC, relative humidity: 40%-60%±5%.

- Check if the device under test and the megger electrode are hygienic. If necessary, clean it with a soft, dust-free cloth dampened with 70% isopropyl alcohol.

- At the time of the first inspection and inspection, at least six product samples are required to be tested.

- The external resistance of the glove is checked. Place the sample to be tested on the insulation board, and then place the electrode of the megohmmeter on the surface of the ESD glove. The electrode does not exceed the sample.

- After the electrode is placed, use the 10V file of the megohmmeter to check the anti-static gloves. If the reading is 1.0X107 ohm, use the 100V file for inspection. After the reading is stable, record the reading and check it.

- Use a simultaneous survey to test other templates. Specification of external resistance: ≥1.0X105 ohms to <1.0X109 ohms

For static gloves, accurate data can only be measured by testing in strict accordance with the test procedure. To better avoid harm to electronic products and chips in the work process.

What are the precautions for choosing anti-static gloves:

- The choice of static-resistant gloves must first clear the application field. The requirements for gloves in different fields are different. Especially in the chemical field, the reagents need to be corrosive, and the gloves can not be used casually. It is necessary to choose anti-corrosion properties and anti-static gloves.

- If the static-free gloves need to have waterproof or anti-corrosion properties at the same time, the gloves must be carefully inspected before use to check whether the surface of the gloves is damaged. Damaged gloves cannot be used.

- Anti-static gloves need to be cleaned and dried after use but can not be baked at high temperatures, if necessary, also sprinkle them with talcum powder to prevent adhesion.

- Anti-static insulation gloves need to regularly check the insulation of the gloves to prevent accidents.

- Anti-static gloves are suitable for use in the corrosive acid and salt environment, but in the corrosive environment are not suitable for the use of anti-static gloves.

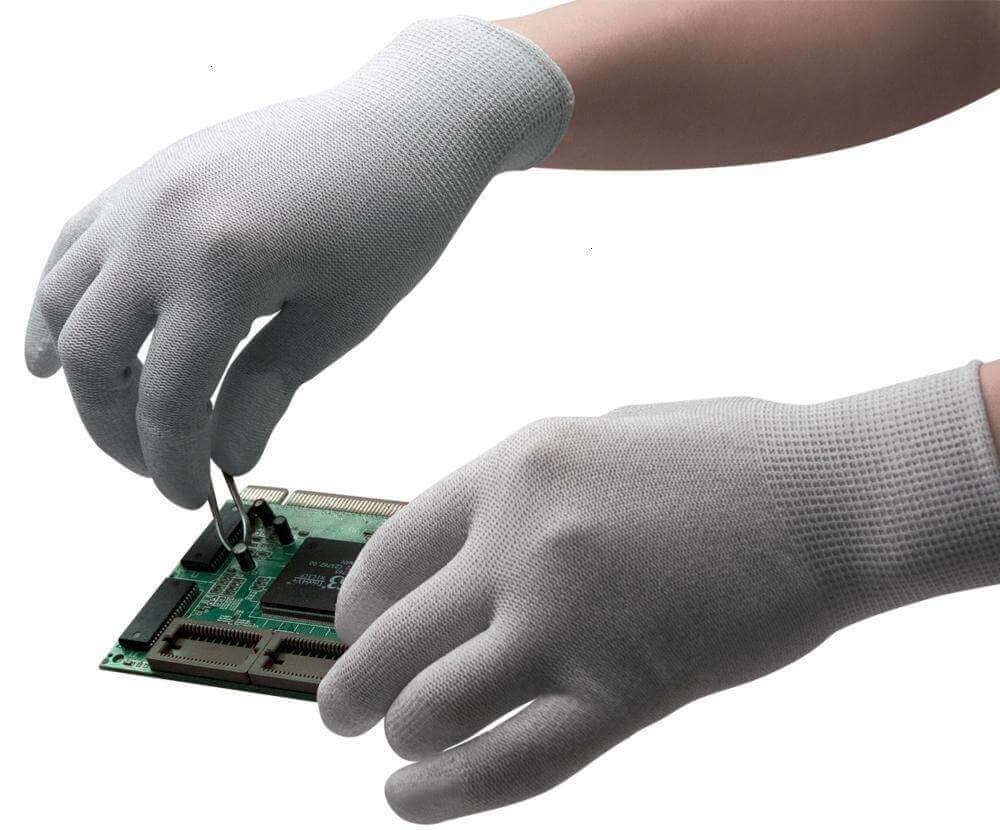

Basic wear common sense of anti-static gloves:

- The staff who operate the ESD components must wear ESD gloves first. The gloves need to use the surface resistance tester regularly for static electricity detection. They also need to wear anti-static overalls. Anti-static clothing and gloves need to use conductive wire. The Polyester fibre fabric can not be made of materials such as ordinary chemical fibre, plastic or rubber which are likely to cause static electricity.

- When operating the electrostatic discharge sensitive components, be sure to avoid physical activity that may generate static electricity in the vicinity. Do not take off the anti-static gloves.

- In some places where the human body can not be used when the sensitive electronic components are packaged, the staff needs to ground themselves first, to prevent the static electricity from the human body from being discharged smoothly and destroying the electronic components.

- Before wearing anti-static insulating gloves, be sure to clean your fingers thoroughly and thoroughly. When cleaning, you can use alcohol or alcohol to add water. Do not use static or chemical fibre to clean the material.

- The staff needs to carry out certain static protection knowledge training. After the training, the ability should be tested and identified. Untrained people and people with unsatisfactory training results are not allowed to assemble and package components.

About PU anti-static gloves

Most of the anti-static coating gloves are made of PU coating technology, which is the best-selling one in anti-static gloves. The PU coating is a polyurethane coating, which is a new development technology in textile finishing. It is a uniform coating of a high-polymer which can form a continuous film on the surface of the fabric.

PU coatings have the following characteristics compared to other coatings:

- Polyurethane coating (PU) agent generally uses adipic acid polyester diol oligomer as raw material, the diisocyanate is commonly used MDI, because MDI has low volatility, low toxicity, high reactivity, and the mechanical properties of the prepared coating film Excellent, and not easy to yellow, is widely used.

- Most polyurethane (PU) coating agents are solvent-based and can be divided into two components and one component. Since the one-component solvent-based polyurethane is simple in construction, the application is more than two components.

- PU coating process generally does not need to be washed, which saves water and reduces sewage discharge.

- The coated fabric changes its appearance and style, and its functionality is increased. High-grade fabrics can be made from low-grade woven fabrics, thus increasing the added value of the products.

- PU coating (ie polyurethane coating) is a waterproof and moisture-permeable fabric that can be used in a special occupation, clothing, anti-static gloves, and curtains and is used to dry the wound, clean and is environmentally friendly!