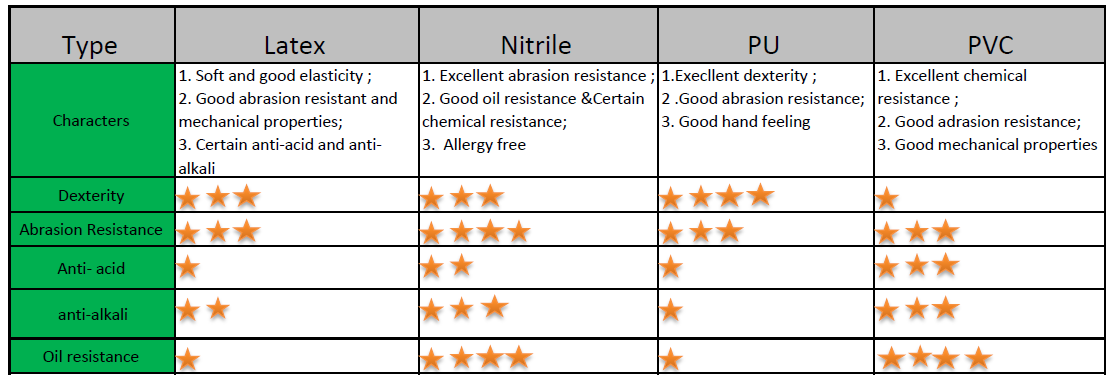

For the coated gloves, now mainly have 4 types of coating, they are Latex, Polyurethane, Nitrile, and PVC. Here we will introduce some details about these 4 types of coating material.

Latex

Latex is a stable dispersion (emulsion) of polymer microparticles in an aqueous medium. It is found in nature, but synthetic latex can be made by polymerizing a monomer such as a styrene that has been emulsified with surfactants. It is a complex emulsion consisting of proteins, alkaloids, starches, sugars, oils, tannins, resins and gums that coagulate on exposure to air. Some people have a serious latex allergy, and exposure to latex products such as latex gloves can cause anaphylactic shock. Guayule latex has only 2% of the levels of protein found in Hevea latex and is being researched as a lower-allergen substitute. Latex gloves have better elasticity and softness than NBR gloves. However, latex gloves have worse abrasion resistance and oil resistance than NBR gloves.

PU (Polyurethane)

Polyurethane is a polymer composed of organic units joined by carbamate (urethane) links. Polyurethane polymers are traditionally and most commonly formed by reacting a di- or polyisocyanate with a polyol. Both the isocyanates and polyols used to make polyurethanes contain, on average, two or more functional groups per molecule. PU gloves are widely used in many industries as they have good dustproof properties, brilliant abrasion resistance, and excellent dexterity.

NBR (Nitrile Butadiene Rubber)

Nitrile rubber, also known as Buna-N, Perbunan, acrylonitrile butadiene rubber, and NBR, is a synthetic rubber copolymer of acrylonitrile (ACN) and butadiene. It is used in the automotive and aeronautical industry to make fuel and oil handling hoses, seals, grommets, and self-sealing fuel tanks since ordinary rubbers cannot be used. It is used in the nuclear industry to make protective gloves. NBR’s ability to withstand a range of temperatures from −40 to 108 °C (−40 to 226 °F) makes it an ideal material for aeronautical applications. Nitrile rubber is more resistant than natural rubber to oils and acids and has superior strength, but inferior flexibility. Nitrile rubber is less likely to cause an allergic reaction than natural rubber. Nitrile rubber is generally resistant to aliphatic hydrocarbons. NBR gloves have excellent abrasion resistance, great dexterity, and good oil resistance.

PVC

Polyvinyl chloride, also known as polyvinyl or vinyl, commonly abbreviated PVC, is the world’s third-most widely produced synthetic plastic polymer, after polyethene and polypropylene. PVC comes in two basic forms: rigid (sometimes abbreviated as RPVC) and flexible. The rigid form of PVC is used in construction for pipe and profile applications such as doors and windows. It can be made softer and more flexible by the addition of plasticizers, the most widely used being phthalates. In this form, it is also used in plumbing, electrical cable insulation, imitation leather, flooring, signage, phonograph records, inflatable products, and many applications where it replaces rubber. PVC is chemically resistant.