You know you need cut-resistant gloves, but do you know what cut level of cut-resistant gloves is suitable for you?

To solve this problem, organizations in both the US and Europe have outlined industry standards for cut resistance in gloves.

For the US Standard, it is the ANSI And for Europe, the standard is EN388:2016 and ISO 13997. These standards are used to determine the level of cut-resistant gloves. In this article, we will talk about it.

Recommended reading:

Cut Resistant Gloves – For The Maximum Cut Protection

Two Main Level of cut-resistant Gloves Standard

For the Cut performance, the market now mainly has 2 standards about the level of cut-resistant gloves:

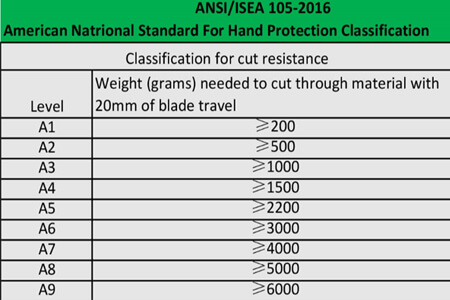

One is The American National Standards Institute (ANSI) has released a new edition of the ANSI/ISEA 105 STANDARD-2016.ANSI standards feature nine cut levels that reduce the gaps between each level and better define protection levels for the cut-resistant glove and sleeves with the highest gram scores.

Another one is Europe standard EN388.

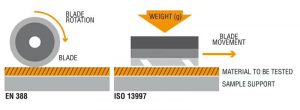

1.The EN388:2016 and ISO13997 of Europe Standard

Europe standard EN388 allows for highly cut-resistant materials to be tested using the ISO13997 test method ISO 13997 testing is similar to ASTM F 1790 testing in that a straight blade is drawn across a piece of fabric as increasing force is applied to the blade. The Cut lever of cut-resistant gloves for 13997 is from A to F grade.

Level 0: These fabrics offer no protection.

Level 1: These fabrics offer protection for cuts considered to be a nuisance to the wearer, such as paper cuts or automotive maintenance.

Level 2: These fabrics offer protection from low-cut hazards such as those that occur in construction, packaging, and some masonry work.

Level 3: These fabrics offer protection from moderate cut hazards from jobs such as light-duty glass handling or light metal stamping

Level 4: These fabrics offer protection from high-cut hazards from applications such as sheet metal handling or food service.

Level 5: These fabrics offer protection from extreme cut hazards from uses similar to plate glass handling and meat/poultry processing.

When buying cut-resistant gloves, you will see that they come with a rating. This is their rating when it comes to their resistance. A pair of gloves with a cut resistance rating of 3 is not as strong as one with a cut resistance rating of 5. You need to assess what kind of work you do and what sort of injuries you subject your hands to, so you can choose the right level of cut-resistant gloves that is suitable for your line of work.

2. The ANSI Standard Of US

The American National Standards Institute or ANSI determines the level of cut-resistant gloves. Since there are no strict recommendations when it comes to the levels of cut-resistance gloves needed for different applications, employers will then have to look at the standards and distinctions set by ANSI to determine what protection they can provide.

(1) The level of cut-resistant gloves 1 or A1 has the lowest rating. They are only capable of withstanding cuts inflicted by 200 g to up to 499 g of a load. It has an abrasion resistance of fewer than 100 cycles and a puncture resistance of no more than 10 Newtons. This can be great for all-around appliances that don’t require heavy usage of sharp objects and equipment.

If you don’t often work with sharp objects, this should suffice. Many industries also prefer this, especially those industries that require a good level of hand dexterity. Use this for the handling of objects, cleaning work, and many other applications that don’t require dealing with sharp tools.

(2) The level of cut-resistant gloves 2 or A2 have an abrasion resistance of no more than 500 cycles, a cut resistance of no more than 500 grams, and a puncture resistance of no more than 20 Newtons.

It is still important to avoid sharp objects when using Level 2 gloves. Although they provide a higher level of protection against abrasions, cuts, and punctures, you should still delegate them to simpler tasks. If you need thin and dexterous gloves to work on more intricate projects, this is a good choice. It can be used for a variety of applications and industries such as in packing, automotive work, shipping, and warehouses.

(3) The level of cut-resistant gloves 3 or A3 enjoy a cut resistance of no more than 1000 grams. The same number is used for abrasion resistance in cycles. It also offers 60 Newtons of puncture resistance.

If you deal with sharp tools and blades occasionally but not too often, this is a good level for you to choose. It is preferred by many industries because it sits in the middle of good hand protection and dexterity. It provides a semblance of protection for the hands but it also enables the hands to move freely. This is the level of gloves to look for by people in the construction, electrical, and pumping industries.

(4) The level of cut-resistant gloves 4 or A4 offer up to 3000 cycles of abrasion resistance and up to 1500 grams of cut resistance. They are also capable of protecting you from up to 60 newtons of puncture force.

Since it offers more protection against injuries, it is best used by people who come into contact with sharp objects like knives, glass, and steel regularly. They can be used in construction, steel handling, car, and glass industries. If there have been a lot of instances of cuts and lacerations in the workplace due to mishandling of sharp tools, get this level of gloves for the employees.

(5) Level 5 or A5 anti-cut work gloves can protect your hands from up to 10000 cycles of abrasions, 3500 grams of cut resistance, and 150 newtons of puncture resistance.

This level of cut-resistant gloves provides the best protection one can get against lacerations, cuts, abrasions, and punctures. As such, it is best used in hazardous workplaces where employees deal with sharp objects like blades, needles, and glass all the time. The downside to this is that it doesn’t provide that much dexterity, so if you need more flexibility in your hands to accomplish more intricate tasks, going down a level might be better.

Decide what level you need first. Do you need more hand dexterity or do you want maximum hand protection? Mull over these things before buying, so the gloves will address your specific needs.