Rubber-coated work gloves can be understood as simple chemical protection on textile gloves of different materials and a layer of rubber material on them to protect hands in different workplaces.

The coated work gloves mainly consist of two parts. One is a glove shell and the other is a coating rubber.

First, the rubber-coated work gloves liner

1. Cut 5 ultra-high molecular weight polyethene fibre (HPPE): the raw material is PE wire, black nylon fibre, glass fibre, white polyester fibre, and spandex yarn.

2. Cut 3 anti-ultra-high molecular weight polyethene fibre (HPPE): the raw material is synthesized into PE wire, black nylon, and spandex wire.

3. Polyester: The characteristics are poor hygroscopicity, good elastic recovery, and durable gloves. Polyester fabrics have good light resistance. The price is lower.

4. Nylon: The characteristics are good moisture absorption, good wear resistance, and comfortable woven gloves. The elastic and elastic renaturation of the nylon fabric is excellent, but it is easily deformed under external force, and the heat resistance and light resistance are both poor.

5. Polyester cotton: composed of very little cotton and polyester. Among them, 6535 polyester cotton consists of 65% cotton and 35% polyester. The price of polyester cotton is relatively cheap.

6. Pure cotton: The characteristic is soft and comfortable, with good elasticity. The price is higher than polyester cotton.

7. Acrylic fibre: The characteristics are soft hand feeling, fluffy hand feeling, bright colour, light resistance, abrasion resistance is the worst, good heat resistance, good warmth, and easy to pile.

8. High-elastic spandex yarn: The characteristic is soft to the touch, and strong elasticity, and woven gloves can be dipped without drying.

9. Cotton jersey: The characteristic is softness is good, only the acrylic fibre, the price is lower.

10. Kevlar: The characteristic is Kevlar is also known as aramid. It is characterized by heat resistance and good fastness. It can not see light. After seeing light, it will change colour. It can be cut and can have 3, 4 and 5 levels. Kevlar yarns are conventional: Kevlar-coated spandex, Kevlar-coated glass fibre, Kevlar coated steel wire.

11. Bamboo carbon fibre: The characteristic is soft and soft. Soft to the touch, good whiteness, bright colour, strong toughness and abrasion resistance, stable, soft and smooth, no tie, softer than cotton, with a unique velvet feel. Sweat-absorbent, cool and comfortable, absorb and evaporate a large amount of water, antibacterial, antibacterial, deodorant adsorption, anti-UV).

12. Polyester-coated spandex yarn, called polyester spandex yarn, features good elasticity, oil and sweat resistance, and polyester properties.

13. Nylon-coated spandex yarn, called nylon-spandex yarn, features good elasticity, oil and sweat resistance, and nylon properties.

Of course, many other types of knitting material can be used as the glove liner. While the above 13 types occupy 95% of current rubber-coated work gloves.

Second, rubber-coated work gloves’ surface

1. Latex

It is found in nature, but synthetic latex can be made by polymerizing a monomer such as styrene that has been emulsified with surfactants. It is a complex emulsion consisting of protein, alkaloids, starches, sugars, oils, tannins, resins and gums that coagulate on exposure to air.

As the rubber surface of rubber-coated work gloves, latex is characterized by softness, elasticity, excellent mechanical properties and low- temperature resistance. At present, the surface treatment of latex is mainly divided into the following types:

(1) Latex crinkle surface, which is characterized by chemical wrinkling, giving gloves a better grip and slip resistance; washing and deodorizing, ensuring that the rubber-coated work gloves have no chemical residue and good hand feeling.

(2) Latex smooth surface, which is characterized by good elasticity and hand feeling, and excellent wear resistance. As well as a long lifetime.

(3) Latex sandy surface, which is characterized by good breathability and good grip function, soft and comfortable, and can be applied in both wet and dry environments.

(4) Latex foaming surface, which is characterized by physical foaming, the pore system gives it excellent texture and elasticity, good air permeability and water impermeability, so that it has a better hand feeling.

At present, latex rubber-coated work gloves are widely used in machinery and industrial equipment, building materials, hardware tools, metallurgy and minerals, automobile and motorcycle assembly and maintenance, etc.

2. NBR (Nitrile Butadiene Rubber)

Nitrile rubber, also known as Buna-N, Perbunan, acrylonitrile-butadiene rubber, and NBR, is a synthetic rubber copolymer of acrylonitrile (ACN) and butadiene.

NBR’s ability to withstand a range of temperatures from −40 to 108 °C (−40 to 226 °F Make it an ideal material for aeronautical applications.

As a glove-impregnating material, nitrile is characterized by artificial synthetic rubber, which has good oil resistance, water resistance, wear- resistance and airtightness, good heat resistance, and strong adhesion.

Disadvantages are low -temperature resistance, poor ozone resistance, poor electrical performance, and slightly lower elasticity.

At present, according to the treatment of the surface of the nitrile, it is mainly divided into the following types:

(1) Nitrile smooth surface, which is characterized by light and sensitive, excellent wear resistance, oil stain resistance, acid and alkali resistance, corrosion resistance and excellent chemical resistance.

(2) Nitrile foaming surface, which is characterized by light and sensitive, soft and comfortable, good hand feeling, excellent breathability and water permeability, and good wear resistance. At present, foaming is divided into ordinary foaming and ultrafine water-washing foaming. Ultra-fine water-washing foam is becoming more and more popular because of its good hand and performance.

(3) Nitrile sandy surface, which is characterized by light and sensitive, soft and comfortable, excellent wear resistance, oil stain resistance, acid and alkali resistance, good hand feeling and slip resistance.

At present, nitrile rubber-coated work gloves are widely used in petrochemical, paint printing, farming and animal husbandry, automotive and mechanical cleaning and maintenance.

3. PU (Polyurethane)

Polyurethane is a polymer composed of organic units joined by carbamate (urethane) links. Polyurethane polymers are traditionally and most commonly formed by reacting a di- or polyisocyanate with a polyol. Both the isocyanates and polyols used to make polyurethanes contain, on average, two or more functional groups per molecule.

As a glove-impregnating material, PU resin is characterized by good electrical insulation, a microporous system, excellent hand feeling, superior elasticity, excellent wear resistance, and tear resistance.

At present, PU rubber-coated work gloves are relatively simple, with only one type of smooth coating treatment. Now also have the water-based PU, which is quite friendly to human skin. While for our company, the technology is not mature, so is not widely produced now.

PU rubber-coated work gloves are widely used in electronic components, electronic mechanical maintenance, precision instrument assembly, agriculture and animal husbandry, light industry, etc.

4. PVC

Polyvinyl chloride, also known as polyvinyl or vinyl, commonly used abbreviated PVC, is the world’s third-most widely produced synthetic plastic polymer, after polyethene and polypropylene. PVC is chemically resistant.

PVC resin is characterized by stability, is not easily corroded by acid and alkali, is relatively resistant to heat, has flame retardant properties, high chemical resistance, good mechanical strength, and electrical insulation, and is not susceptible to ageing.

The disadvantage is that it is not easily decomposed and has low cold resistance.

For the PVC coating, also divide into PVC smooth-coated, PVC foam-coated and PVC sandy-coated. (Because of the PVC’s unfriendly to environmental reasons. now PVC suppliers have become fewer and fewer)

At present, PVC rubber-coated work gloves are widely used in building materials, machinery maintenance, metallurgy, and minerals.

Summary: Different glove liners combined with different coating material supply the different usage in different workplaces. This combines means to continue testing and researching on it day by day. Only want to meet our ultimate goals to make your hand safe and make your life happy.

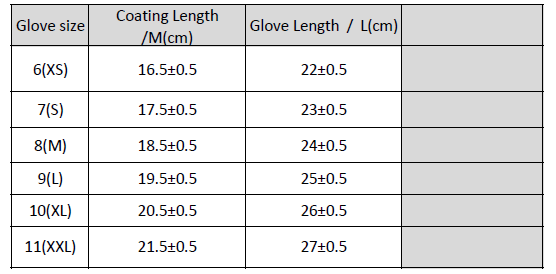

Third, a Comparison of Four Coating Materials

This form will give us a brief knowledge of different coating materials:

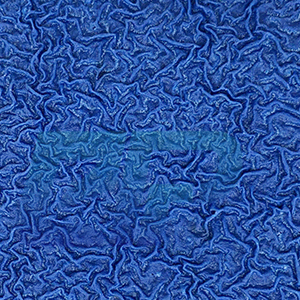

Fourthly, the production process of rubber-coated work gloves

This picture will show a general process for the rubber-coated work gloves.

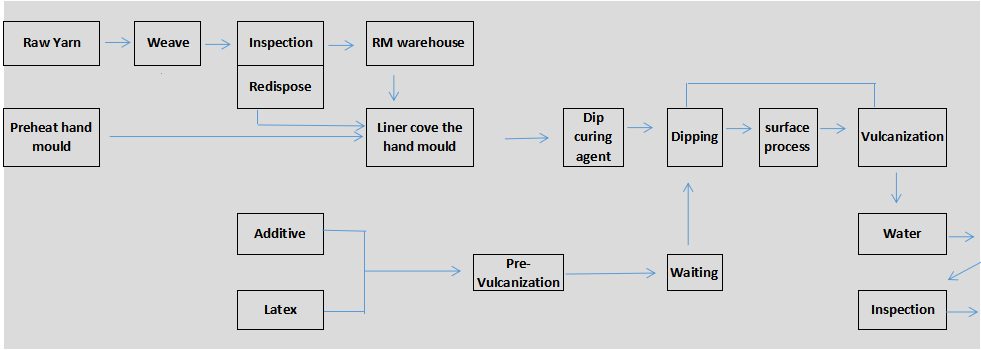

Fifth, the dipping length for the different coating positions

According to different dipping positions, the rubber-coated work gloves include palm-coated gloves, half-coated gloves and fully-coated gloves.

Here we listed the dipping length requirement during our production for your reference.

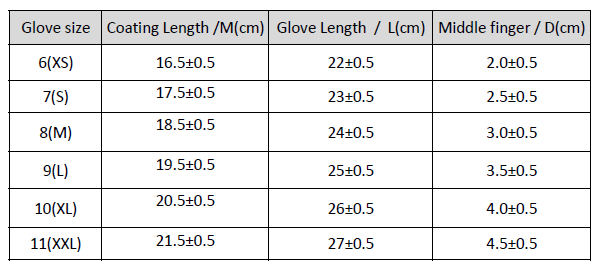

Palm-coated size specification:

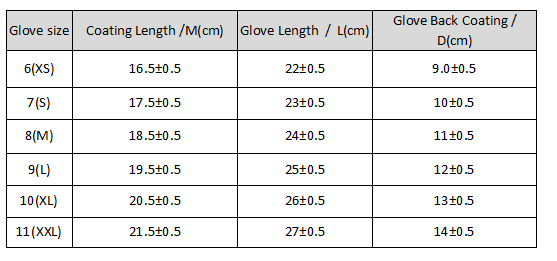

Half-coated size specification:

Fully-coated size specification: