What are the characteristics of PU coated gloves?

- The past few years have seen an increase in popularity for PU coated gloves or Polyurethane-coated work gloves, especially in manufacturing industries. Many industries have since replaced their leather gloves with PU coated gloves because of the benefits these non-disposable gloves provide.

- These days, PU coated gloves come in a variety of colors and purposes. With a high score on the EN388 mechanical score garnering impressive ratings for abrasion, it isn’t surprising why many industries prefer using these gloves today.

- The surface resistance of the polyurethane(PU) gloves can reach 10 7th ohms. During the use of the PU glove, the fingertip friction does not easily generate static electricity and has no adsorption capacity to the surrounding dust. At the same time, the PU resin does not contain silicon, and after contact with other objects, it does not leave marks and sweat marks. PU-dipped gloves are widely used in the dust-free purification space, electronics industry, and semiconductor industry.

- Features of PU coated gloves: good electrical insulation, microporous system, excellent hand feeling, superior elasticity, excellent wear, and tear resistance.

- Common glove shells for PU work gloves are 13/15 gauge polyester, 13/15/18 gauge nylon(polyurethane-coated nylon gloves), and 13/15 gauge carbon fibre (also there is a very hot-selling cut-resistant HPPE with PU coated work glove, we will give more details in the section of Cut Resistant Glove ). The long-fibre polyester nylon is woven into the copper wire conductive fibre/carbon wire anti-static fibre so that the glove has the effect of not sticking to the skin. The static electricity is prevented from generating fine dust under the potential, and the working environment is clean and comfortable.

- Polyurethane palm-coated gloves have higher abrasion resistance than latex and the same as nitrile. It is the lightest in hand and at a lower price than latex and nitrile, so g40 polyurethane-coated gloves are highly recommended.

The Anti-static PU Coated Gloves

PU coated gloves generally have a common type and anti-static type. Below we introduce the anti-static PU coating gloves in detail.

Material:

80% nylon plus 20% high-performance copper fiber/carbon fiber woven;

Apply PU resin to your fingers or palms.

Performance:

- The conductive coating resin is added to the PU coating to make the antistatic effect the best. It can avoid the direct contact of the operator’s fingers with the electrostatic sensitive components, and can safely discharge the static charge of the human body.

- Has good anti-slip and wear resistance.

- Good gas permeability and washable.

Surface Resistance:

Carbon fiber 10^7Ω-10^8Ω

10^5Ω-10^6Ω of copper fibre

Nylon, also known as polyamide, is a synthetic fiber. Its advantage is that it has a higher wear resistance than all other fibers and is not easy to break. The gloves made of nylon have the advantage of not being off-line and durable. It fits tightly with your fingers and does not cause any discomfort. Many workers in the workplace feel that the gloves are sticky and not easy to use under long working conditions, but this will not, nylon anti-static gloves are non-slip. The effect is strong, there will be no slippage of the product from the hand, and the anti-slip property is also guaranteed.

In nylon gloves, conductive fiber is used. Conductive fiber refers to a certain chemical fiber or metal fiber, which has a very strong antistatic effect, and the humidity does not have any influence on its electrical resistance. The acquisition of the conductive fiber is not as expected. It is easy to use, such as miscibility, evaporation, electroplating, etc., and is made by mixing with carbon black, graphite, or metal powder. The conductive fiber material in the antistatic glove has a good electrical insulation effect and antistatic function.

At present, the anti-static gloves we are talking about are nylon-blend conductive fibers or polyester-mixed conductive fibers. The price of polyester is cheaper than nylon, and the comfort and life of use are also worse.

Benefits of PU Coated Gloves

So, what is the particular lure of PU coated gloves? What makes these gloves such as a hot commodity in the manufacturing industry?

-

These gloves can be made thinner.

Depending on the liner used for these gloves, they are thinner than your standard work gloves. Why is this better? It’s because it provides a higher level of hand dexterity. Since these gloves are thinner, one can feel better using them. It’s a great choice for industries where workers need to feel what they are working on such as in automotive industries or industries that manufacture or assemble small products.

-

It provides a good level of safety.

The high level of dexterity contributes to the safety of these gloves. Since workers tend to feel what they are working on better, they can perform better. This reduces the risks of injuries in the workplace. Additionally, since these gloves are thinner, they minimize hand fatigue which means workers are more likely to wear their gloves.

-

They are affordable.

In an industry that requires a lot of these gloves to be used by their workers daily, polyurethane-coated gloves are more affordable. The price depends on how thick the material is or what kind of liner is used but if you have a certain budget you want to stick to, you are bound to find PU coated gloves that will work for you. Each pair of PU coated gloves, even the high-quality ones cost 1/3 of the average price of general-purpose gloves.

-

They offer excellent grip.

The polyurethane coating of these gloves makes the surface of the gloves tacky. It will then offer a better and more effective grip, great for industries that handle smooth and slippery objects.

How to Choose PU Coated Gloves

Because of the wide range of PU coated gloves out in the market, you find yourself challenged with the prospect of finding one for your business or industry. But here are a few factors you need to consider to get the right PU coated gloves for your needs:

-

Level of protection

Since PU coated gloves have different cut resistance levels and different materials and liners included, you need to identify your personal needs first. If you frequently work with materials that have a high risk for injuries, opting for a high cut level is important.

Find out how well the gloves can protect you from abrasions and cuts, which are important in preventing injuries. Most PU coated gloves manufacturers will indicate the cut-level safety of the gloves they are offering.

-

Comfort

The comfort of the gloves has a lot to do with how thick or thin they are. The thicker the gloves the less flexible they are going to be. If you need a high level of dexterity for the industry you are in, make sure you opt for thinner and more comfortable PU coated gloves. They should offer breathable features as well so that the hands won’t get sweaty and the workers won’t feel uncomfortable using them even for extended periods.

-

Weight

Like the other categories, PU coated gloves can come in different weight levels. For extended wear, lightweight PU coated gloves are better as they can avoid hand fatigue.

Best Lining Material for PU Coated Gloves

When it comes to the lining material, you should look for PU coated gloves that have a combination of nylon and polyester materials. These materials are more breathable than other textile materials, so air can circulate better, thereby preventing overheating and sweating.

PU Coated versus Latex Coated versus Nitrile Coated – Which is Better?

- These types of gloves offer different benefits. Which one is the best choice will depend on your needs. If you prefer or need a high level of dexterity but without sacrificing on price and protection against cuts and abrasions, the best choice is a PU coated glove. It is also more affordable compared to Nitrile-coated ones. These gloves are great for those industries that require a balance between functionality and comfort. These are the gloves you should look for as well if you want the best suction and grip.

- Latex-coated gloves can be used for applications that don’t require too much hand protection. It is also cheap, great for people who are on a budget. However, because it is made from natural latex, there is a good chance that it can cause allergic reactions in people with sensitive skin. If you have workers who might be sensitive to latex, this might not be the best option.

- You can switch to nitrile-coated gloves as an alternative instead. It is made from synthetic materials that make these gloves more resistant to wear and tear. They also provide better protection for the hands when it comes to abrasions and cuts. That makes these gloves better for industries and businesses that often subject the hands to a lot of injuries. The downside is that these gloves are more expensive and they are not as good with tactility compared to PU coated gloves.

- We also suggest using nitrile-coated gloves for handling wet or oily applications. It has excellent moisture and oil-resistant properties, which is what makes this a good option for those handling greases such as in automotive industries and those that handle chemicals.

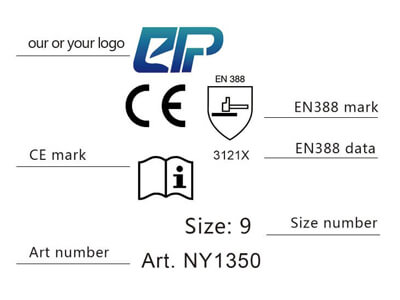

General Printing Of Safety Glove With Coating

Conclusion

PU coated gloves are great for a variety of applications. But since they come in different thicknesses and sizes, make sure you get the ones that will suit the needs of your business.