Characteristics of nitrile-coated gloves

Nitrile-coated Gloves is a high-quality hand protection equipment that combines the advantages of Nitrile Rubber and Natural rubber with excellent chemical resistance and dexterity. It is widely used in various harsh industrial environments and can effectively protect hands from chemicals, oils, and high temperatures.

Why choose NITRILE?

- Nitrile has good physical properties, good tear resistance, puncture resistance and anti-slip. Excellent chemical resistance, certain pH resistance; Good chemical protection for corrosive substances such as solvents and petroleum; The degradation time is short, easy to handle, and environmentally friendly. These features make nitrile gloves a very popular work glove.

- Compared with latex, nitrile has the disadvantage of poor elasticity, and its advantages are oil resistance, abrasion resistance, chemical resistance, and acid, and alkali resistance.

- Nitrile-coated gloves are widely used in petrochemicals, paint printing, farming and animal husbandry, automotive, mechanical cleaning and maintenance of building materials, hardware tools, metallurgy and minerals, and other industries.

- The nitrile-coated glove is a glove made of synthetic rubber. The main components of nitrile are acrylonitrile and butadiene.

- The nitrile rubber and the knitted liner are mixed to form a nitrile-coated coating glove.

Why choose nitrile-coated gloves?

The work environment today poses many risks to the hands. From cuts to burns, there are a lot of injuries that a person can sustain while doing their job.

This is the reason why wearing safety equipment such as work gloves is imposed in industrial workplaces. One such important safety equipment that modern-day workers can wear is the nitrile-coated glove.

Nitrile-coated gloves, unlike regular gloves, are non-disposable. It is similar to synthetic rubber components except that it contains Nitrile. This is a kind of copolymer that goes through a manufacturing process that is also quite similar to regular rubber gloves. The difference is that it is made from Nitrile, which is considered a synthetic substance, which means it reduces the likelihood of allergic reactions.

Work gloves coated with Nitrile tend to be less stretchy though compared to those crafted from natural rubber. It is also not as grippy as natural rubber. However, it brings durability to the table. Gloves made with Nitrile tend to last longer, making this an excellent choice in industrial settings.

The lack of natural latex proteins in nitrile-coated gloves gives them more ability to withstand wear and tear. They can also be relied on for safety because of their high puncture-resistant properties. Compared to natural rubber work gloves, these nitrile-coated gloves are three times more durable.

Aside from that, nitrile-coated gloves can withstand oil and have excellent chemical-repelling properties. That said, these gloves are often recommended for use in the automotive industry as well as in various industries where handling chemicals and oils is a daily occurrence.

What are the different kinds of nitrile-coated gloves?

- According to the nitrile surface process, including smooth nitrile, sandy nitrile coated gloves, foam nitrile work gloves, double layer nitrile safety gloves, and so on.

- According to the liner material, nitrile-coated gloves include polyester liner, nylon liner, nylon with spandex liner, cotton jersey liner, cotton interlock liner, HPPE liner and so on.

- According to the coated position, including palm-coated nitrile work gloves, half-coated nitrile-coated work gloves, fully-coated nitrile work gloves, and double-layer nitrile-coated gloves.

1) Palm nitrile-coated work glove

For nitrile palm-coated work gloves, nitrile rubber does not have any surface treatment. It is characterized by excellent wear resistance, light and sensitivity, oil stain resistance, acid and alkali resistance, corrosion resistance and excellent chemical resistance.

13 gauge polyester or nylon with firm grip nitrile coated work glove, this is the most common design all over the world. As it has good feeling and reasonable price, these gloves are a good function of resistance to abrasion. The liner can use nylon instead of polyester, nylon has a longer lifetime and is softer than polyester. Also, the liner can use the 15 gauge polyester or nylon, the 15 gauge liner is thicker than the 13 gauge liner, which makes the glove more comfortable.

U3 style polyester or nylon liner, which provides more anti-slip function for the nitrile work gloves.

Cotton interlock brushed liner. After the brushed surface, the surface has a rich and fluffy cotton fabric, which is soft, supplying a comfortable feeling and good warmth function. In the market, cotton interlock liners usually sewing with a safety cuff or knitting cuff. This kind of glove we also called heavy-duty work gloves.

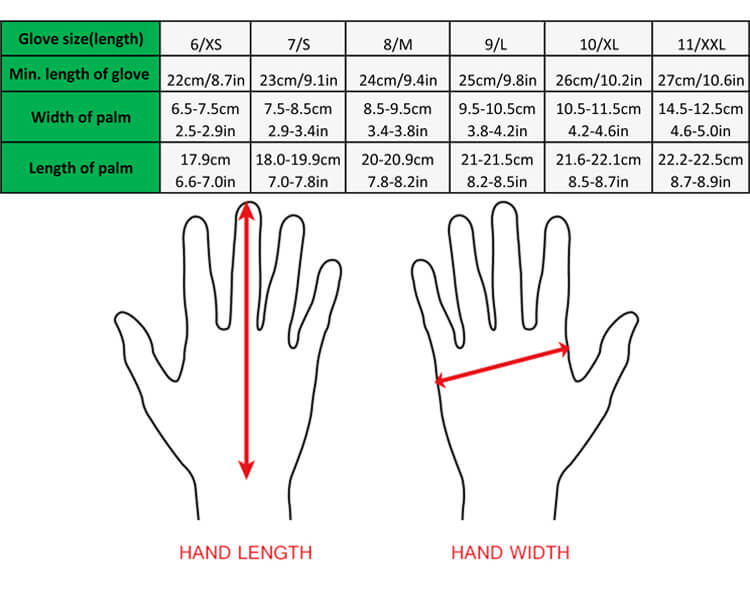

EN420 General Requirements And Other Size Demand For Nitrile Work Gloves

2. Fully Coated Nitrile Gloves Benefits

There are different kinds of nitrile-coated gloves out there. Some have a coating only on the fingers and the palm. These nitrile-coated gloves are better when it comes to grip. Although thin, they are still highly durable and can provide tactility. The materials used are also breathable and resistant to cuts and snags.

You can also find fully coated Nitrile gloves. Just like what its name suggests, fully coated nitrile gloves are the ones with a coating of Nitrile all over the gloves, not just one part. As a result, all the parts of the gloves get the benefits of Nitrile coating.

Aside from full protection against abrasions and punctures, fully coated nitrile gloves can also be used to protect the hands from the cold. Workers in cold environments or those living in countries with cold climates can benefit from using this type of gloves.

The high level of dexterity that can be provided by fully coated nitrile gloves also makes this an ideal choice for industries that require a lot of hand movement and sensitivity.

Nitrile versus Latex Coated Gloves – Which is Better?

- You already know about nitrile-coated gloves. Now, it’s time to find out more about latex-coated gloves and find out which of them is the better choice.

- Latex is a material that is taken from rubber trees. These are the materials commonly found in commercial gloves that you can buy in the market. In the past, they are the preferred choice for medical purposes and cleaning.

- These days though, more and more industries are turning to nitrile-coated gloves for the same reasons pointed out above. Nitrile-coated gloves offer better quality and resistance to damage than regular latex gloves, making them a better choice for various applications.

- On a scale of 1-10, the chemical resistance of nitrile-coated gloves is at 10 while latex is only at 5. The puncture résistance of nitrile-coated gloves is also at 10 while the puncture resistance of latex gloves is only at 4.

- Nitrile-coated gloves are also better for allergy sufferers with a minimal allergy rate of 1% compared to the 3% allergy rating of latex.

- On the other hand, latex wins when it comes to dexterity, offering better sensitivity to users. It is also more biodegradable compared to nitrile-coated gloves.

- At the end of the day, which one you should choose will depend on the needs of your industry. If your work demands that you have better protection for your hands against punctures and chemicals, it makes sense to invest in nitrile-coated gloves even if they are more expensive. After all, it’s better to prevent injuries from happening rather than buy cheap gloves and let injuries cripple the workplace. It will affect safety and productivity.

Frequently Asked Questions About Nitrile-Coated Gloves

To have a better understanding of what nitrile-coated gloves can do, here are a few frequently asked questions about them you need to know:

-

Who Should Use Nitrile-Coated Gloves?

Anyone in need of better hand protection when working can use nitrile-coated gloves. It is also advisable for people with severe latex allergies. However, it is quite beneficial for the automotive industry where workers tend to handle small and oily objects a lot. It can also be used in the manufacturing, maintenance, agriculture and horticulture industries.

-

Are Nitrile Coated Gloves Waterproof?

Not all nitrile-coated gloves are completely waterproof. Some are just water-resistant. However, if you go with the sandy-finish nitrile, you can get better water-resistant properties. When buying nitrile-coated gloves, find out what finish you are getting and make sure you are buying one that has the right level of water resistance for your needs.

-

Can Nitrile Coated Gloves Trigger Allergies?

The good thing about nitrile-coated gloves is that it is devoid of the latex components in regular gloves that can trigger allergies. This is why it is a better choice for people with allergies. However, if you still get an allergic reaction, consider switching to nitrile gloves without the powder inside. That can help prevent an allergic reaction.

-

What do nitrile gloves protect against?

Nitrile gloves are best used for puncture and abrasion resistance. They are a great investment for industries that handle sharp objects a lot. It can also offer a good level of protection against water, oils, and chemicals.

Consider choosing nitrile-coated gloves for the protection of your hands.