With so many Work Gloves manufacturers in China, it is crucial to choose a reliable and efficient partner. Whether it is in terms of quality, delivery time, price or service, it needs to be well thought out. A good partner not only provides quality products but also helps companies reduce costs and improve operational efficiency. So facing so many work gloves manufacturers, how should you make a choice?

Please see below 10 suggestions that may help you:

1. Familiar with and understand the main distribution of different types of gloves.

Cowhide gloves are mainly produced in Guangzhou, China, Jiangxi and Hebei, and Pakistan. Disposable rubber gloves have the advantage of raw materials because of Malaysia’s unique natural climate. At the same time, there are also disposable work gloves manufacturers in Hebei, China. Knitting line gloves are mainly produced in Linyi, Shandong, China and Pujiang, Zhejiang.

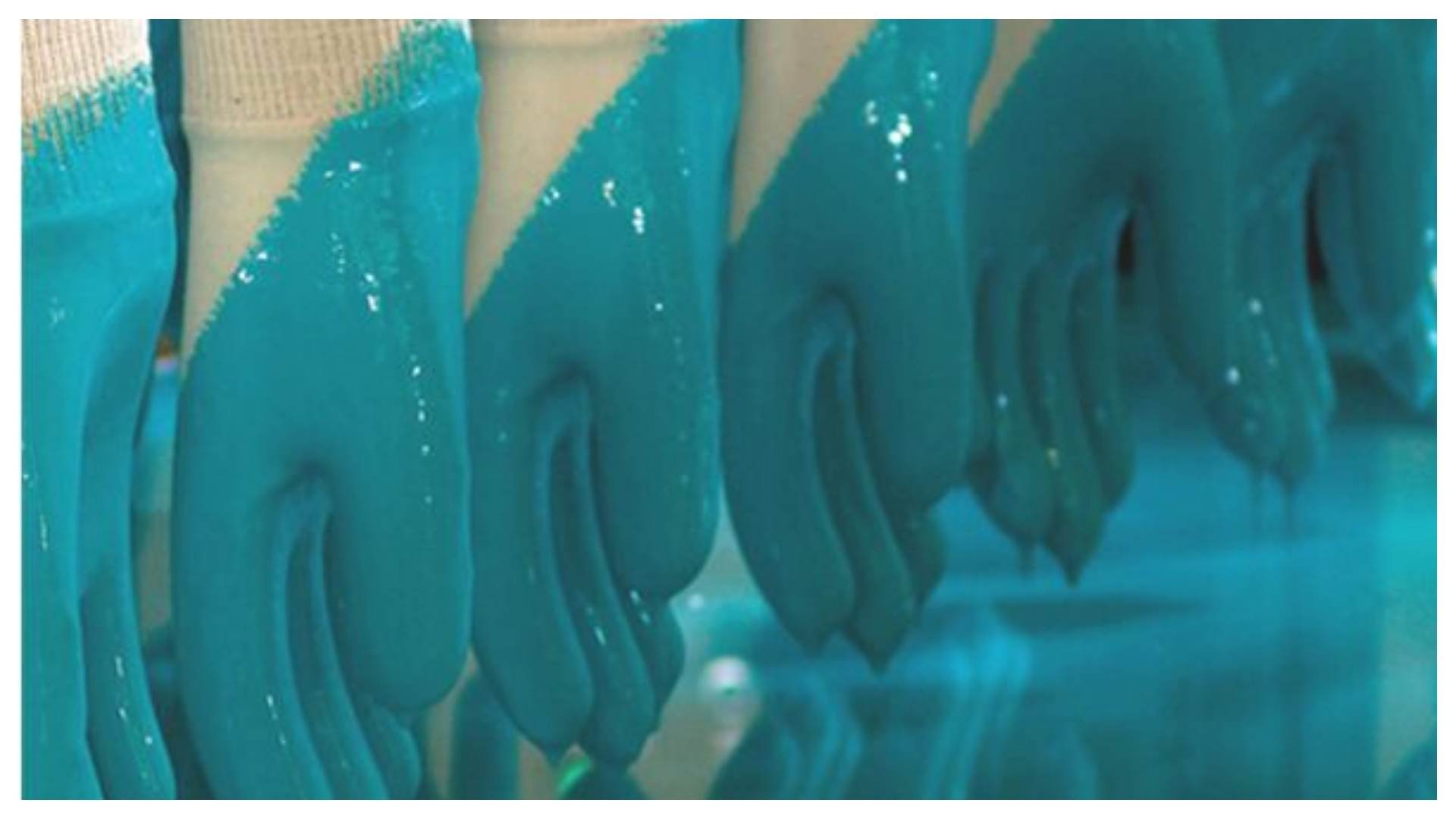

The dipped labour insurance gloves are mainly concentrated in Nantong, Jiangsu, and Shandong Gaomi, because of their unique supply chain and related supporting advantages, labour advantages. These areas are the main production areas for the gloves, and of course, there are other places. Only industrial clusters are more in the above places.

2. Understand the most basic glove production process.

Different types of work gloves, required machines, technical processes, labour allocation, and related supply chain packages are not the same. Therefore, as a purchase should be clear and understandable, the manufacturer of cowhide gloves can’t provide dip gloves at the same time, disposable rubber gloves and dipped gloves have nothing to do with production. Therefore, when purchasing additional types of work gloves, buyers should not attempt to buy completely different types of gloves from a work gloves manufacturer.

3. Quality factors: Quality is the root of everything.

Quality is the survival of the supply chain. The use-value of the product is based on the quality of the product. It determines the quality of the final consumer product and affects the market competitiveness and market share of the product.

Therefore, product quality is one of the most important factors in selecting a work gloves manufacturer. Quality includes the quality of the product itself and the stability of the quality itself. The quality of work gloves, to a large extent.

It affects its price, comfort, service life and safety. Therefore, the quality of protective equipment is more important than the price.

The ideal state is to find the perfect match between price and quality. The quality control of dipped gloves, from raw material procurement to finished product delivery, is a complex and complete system.

In most cases, the production of the work gloves manufacturer is carried out according to the quality of the sample confirmed by the customer and the quality of the sample. The production process is subject to a random inspection of the elimination of food, and the problem is corrected in time.

At the same time, the finished product needs its testing equipment inside the factory to test the wear resistance, cutting performance and tearing performance. Some products are sent to professional institutions for testing according to customer requirements.

4. Price factor

Not the best price, but a reasonable price.

The low price means that the purchaser can reduce the cost of procurement, and has a significant effect on the company’s competitiveness and profit increase. It is an important factor in selecting work gloves manufacturers.

However, the lowest-priced work gloves manufacturer is not necessarily the most suitable, especially for dip-type protective gloves, the same size and weight of the gloves, the amount of glue may vary greatly, and the origin of the raw materials are different, which will lead to huge differences in prices.

The amount of glue is the most important factor in glove comfort and function. Many unprofessional buyers will only use price as a reference factor to determine purchasing behaviour. At the same time, different companies’ labour costs as well as scrap rate and quality control are also different, and will also cause large differences in prices.

So when you are choosing a work gloves manufacturer, price is not the main factor. Always look for a reasonably priced supplier with a guaranteed profit margin, which will ensure the quality of your purchase.

5. Delivery punctuality

Whether the products can be delivered on time and at an agreed time and place directly affects the continuity of the company’s production and supply activities.

It will also affect the inventory level of the supply chain at all levels, which in turn will affect the company’s response to the market, and interrupt the producer’s production plan and the seller’s sales plan.

Simultaneous delivery is also a reference for measuring a company’s production management capabilities and integrity. Any work gloves manufacturer must deliver the goods in time according to the contract. If there is any force majeure factor to delay delivery, the buyer must be informed in time.

In the production of rubber gloves, the production quantity of a fixed variety of production lines is fixed. Therefore, the determination of the production date is also based on production capacity. In the absence of force majeure, the delivery period is naturally fixed.

6. Integrity

We can accept the defect but do not accept deception.

“Integrity” is the bottom line of the purchaser and the principle of adherence. It is unable to arrive on time, the quality of the product cannot meet the required standards, and the production cannot be completed.

This series of problems will expose the work gloves manufacturer’s shortcomings, but it still needs to be truthful feedback in advance. For the purchaser, it is forbidden to drag it to the last moment, so that the buyer is irreparable and suffers losses. What is more serious is that some manufacturers clearly know the problems and still try to hide the purchasers or delay the time. For such manufacturers, buyers can’t cooperate with them.

At present, there are many work gloves manufacturers in the market that attract customers at low prices, and at the time of production, they rely on lowering the quality (reducing the rubber content and neglecting the quality control) to obtain profits. Some quality problems in the production process try to cover up, shoddy. The final result is not only that the buyer bears the loss, but more importantly, the behaviour of reporting low prices seriously disrupts the normal order of the market. At present, this rampant phenomenon seriously undermines the normal work glove market order. We believe that this approach cannot stand the test of time. Will eventually be eliminated by the market.

7. Choose the Work Gloves Manufacturer or Trading Company.

Choose a work gloves manufacturer or a trading company, mainly considering the following points:

Price:

Sometimes, the work gloves manufacturer’s offer is more competitive.

The advantage of a foreign trade company is that it can hoard a batch of orders and give it to a factory at a time, thereby obtaining a lower price. They then split the goods and distribute them to individual customers.

Therefore, sometimes the price of a foreign trade company may be cheaper than the factory. At present, in the procurement of small-volume and multi-variety safety gloves, the low-order quantities of the foreign trade companies and the complete work gloves are more easily recognized by customers. Many excellent foreign trade companies have also developed rapidly.

Quality Control:

The factory can control product quality for the first time.

Foreign trade companies need a stricter product management and control system, as well as product inspection personnel, to achieve product control purposes.

Communication skills:

In this respect, most factories are in a weak position.

The factory generally does not have professional foreign trade practitioners or does not understand the buyer’s behaviour and cultural background, and the foreign trade company has accumulated rich experience, understanding ability, and foreign trade process operation ability and service awareness is better than the factory, thus saving purchases.

Business communication and time cost, this is also the main source of profit for work gloves foreign trade companies. At present, the providers of labour protection products in China, foreign trade companies and factories each account for about 50% of the proportion.

Other work gloves suppliers:

Safety Work Gloves Suppliers South Africa

Safety Work Gloves Suppliers Singapore

Bulk Wholesale Work Gloves Suppliers Australia

Wholesale Work Gloves Suppliers UK

Safety Work Gloves Wholesale Suppliers USA/Canada

8. Time and experience

Experience is not equal to excellence, but largely determines the ability to meet problems and integrate resources.

There are many types of protective gloves and the quality is very different. Therefore, for protective gloves manufacturers and trade, it has been successful in mastering high-quality supply resources and supply chains.

The acquisition of these high-quality resources requires time to accumulate, and it is necessary to constantly try and try until the screening can be finally certified. Therefore, an experienced work gloves manufacturer is not necessarily a good manufacturer, but a good manufacturer is time. Experienced manufacturer.

9. The ability to solve problems

For anyone who has a problem, the given solution is more important than the find problem.

Quality issues, delivery issues. When these problems arise, suppliers should promptly and strive to give solutions, rather than evade and cover up the problem, and bear the responsibility of the commitment, only then, the business can be long-term

10. Professional knowledge and skills

Another point that buyers value is the familiarity of foreign trade salesmen with companies, products, and markets. If a salesman knows nothing about the company’s product line or knows a little about it, the buyer asks the relevant technical staff if he asks any professional questions. The salesman will lose the buyer’s confidence in him. At the same time, based on strong professional knowledge, we should also be flexible in dealing with various accidents.

Of course, there are many factors in choosing a work gloves manufacturer. I hope that we will explore more research opportunities, and we will learn valuable experience and improve our product quality and service level.