What is EN388?

EN388 is a European standard for personal protective equipment, particularly hand protection. It specifies performance requirements for gloves and other hand protection to protect users from potential hand injuries in the workplace.

EN388 assesses four main aspects of glove protection: abrasion resistance, cut resistance, tear resistance and puncture resistance. These tests include rubbing samples under certain pressure and cut, tear and puncture tests that simulate actual use. Based on the test results, the gloves will be rated at different levels to meet the protection requirements of different workplaces.

In addition, apart from the basic performance requirements mentioned above, EN388 also stipulates the requirements for glove comfort, sizing and materials. For example, the gloves must fit the user’s hand size, and the material must be breathable and not produce allergic reactions.

Overall, the EN388 standard is a comprehensive assessment of the performance and quality of gloves, providing users with a reliable basis to help them make the right decisions when selecting suitable hand protection equipment.

EN388:2016 For Working Glove

Protective gloves against mechanical risks-EN388 Standards

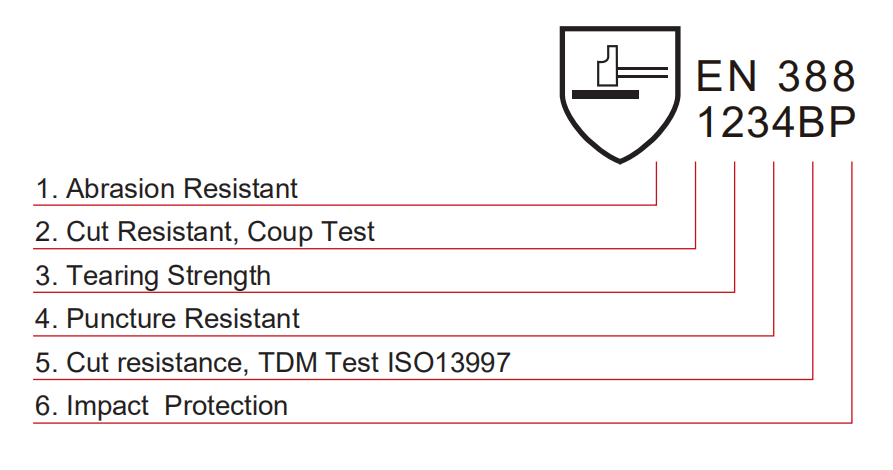

According to this standard, characteristics such as abrasion resistance, cut resistance, tearing strength, puncture resistance, and impact protection are tested. In conjunction with the pictogram, four numbers and one, or two letters, will be displayed. These signs indicate the performance of the glove.

1. Abrasion resistance

The material is subjected to abrasion by sandpaper under a determined pressure. The protection level is indicated on a scale of 1 to 4 depending on the number of turns required until a hole appears in the material. The higher the number is, the better the abrasion resistance.

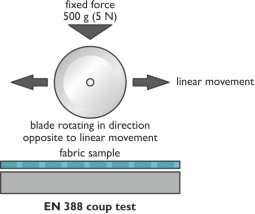

2. Cut resistance, coup test

The cut protection is tested. A knife is passed over the glove material until it cuts through. The protection level is given by a number between 1 and 5, where 5 indicates the highest cut protection. If the material dulls the knife during this test, the cut test ISO 13997(TDM test) shall be performed instead, see point 5.

3. Tearing strength

The force required to tear the glove material apart is measured. The protection level is indicated by a number between 1 and 4, where 4 indicates the strongest material.

4. Puncture resistance

Based on the amount of force required to puncture the material with a tip. The protection function is indicated by a number between 1 and 4, where 4 indicates the strongest material.

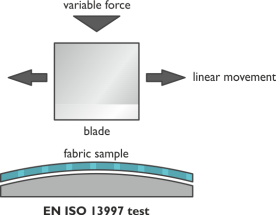

5. Cut resistance, TDM test ISO 13997

If the knife gets dull during the coup test, see point 2, this test shall be performed instead. The result is given by a letter, A to F, where F indicates the highest level of protection. If any of these letters is given, this method determines the protection level instead of the coup test.

ISO 13997B1999 – Determination of resistance to cutting by sharp objects

An alternative cut test is recommended for cut protection gloves. Shall be used in EN388:2016 for cut protection gloves where the cut material dulls the cutting knife during testing. A knife cuts with constant speed but increasing force until the breakthrough of the cut protection material. The level of protection is given in Newton, the force needed for cut through at 20mm cut length.

6. Impact protection

If the glove has impact protection, this information is given by the letter P as the 6th and last sign. If no P sign, no impact protection is claimed.

In addition to the above performance requirements, EN388 also provides more detailed regulations on the materials, dimensions and structural design of gloves to improve the comfort and safety of gloves. At the same time, the test methods and rating standards for the properties of cut resistance, tear resistance and puncture resistance of gloves have been revised and improved to better reflect the actual use of gloves.

In addition, the EN388 standard also adds new requirements and test methods for the anti-static properties of gloves, to improve the safety of gloves in flammable and explosive environments.

Overall, the EN388 standard is a comprehensive assessment of the performance and quality of gloves, providing users with a reliable basis for selecting appropriate hand protection equipment.